Cage| Automatic cage window milling machine processing case

Crafting process

Workpiece case

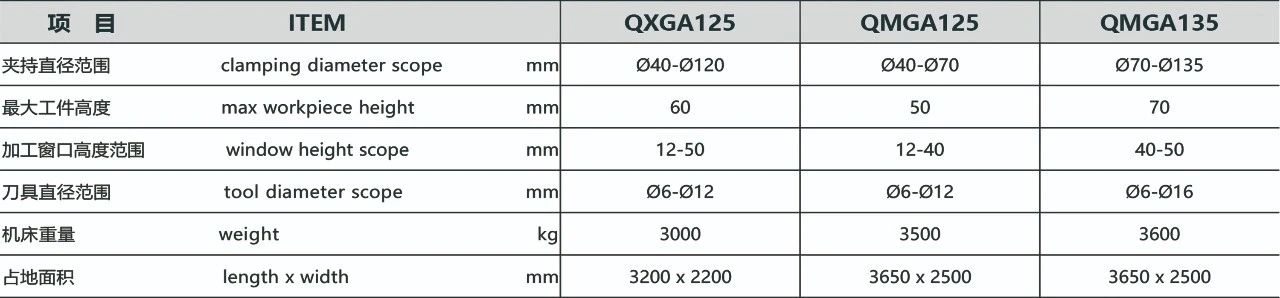

| Workpiece name | Cage |

| Machine type | QXGA125 |

| Manufacturing procedure | Window milling |

● One time clamping can complete the CV joint cage window milling or grinding;

● Solid casting body, high rigidity rectangular hardened guide rail, durable;

● The milling axis is vertically adjusted, and the milling quantity and height error of the upper and lower milling surface of the window can be adjusted at will.

● Servo driven workpiece shaft, high frequency rotation and accurate circular bisection;

● Special pneumatic fixture, clamping reliable, stable precision;

● It can be equipped with truss or joint robot to support automatic wire connection.

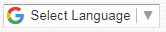

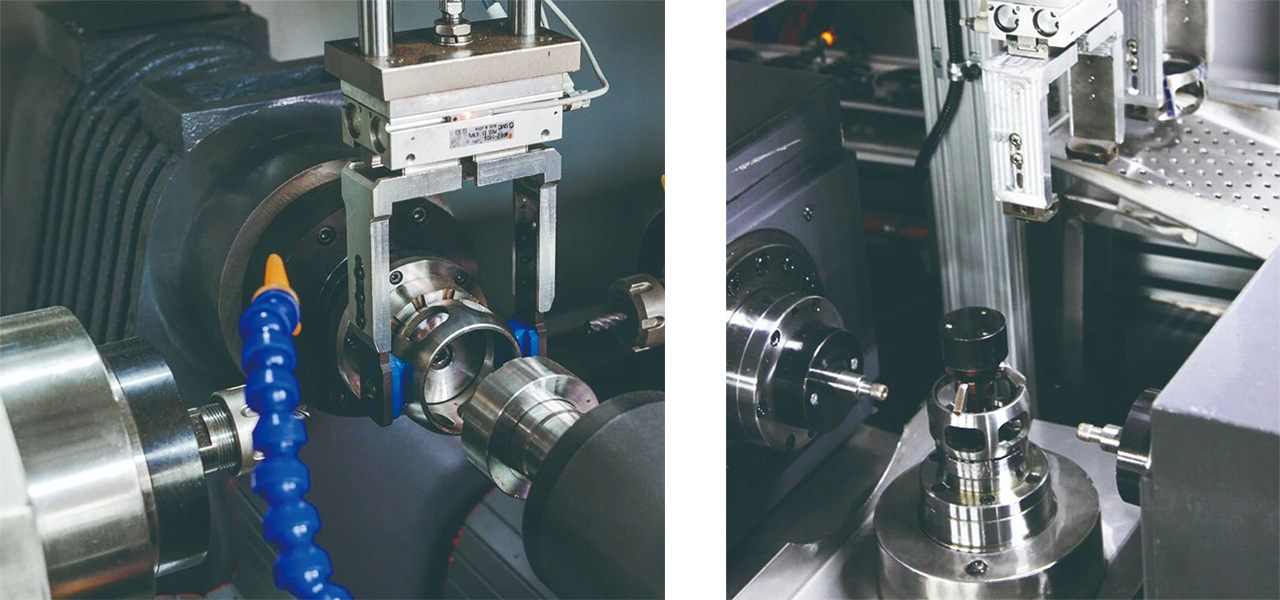

There are two symmetrically arranged power sliding tables on the whole bed of the machine tool, each of which is equipped with a milling power head to complete the feed and advance movement of the cutter, among which the spindle for workpiece indexing and rotating feed is arranged on the intermediate base to complete the six slots free indexing and rotating feed when the workpiece is processed. The equipment is a horizontal combination structure.

1、It is suitable for precision milling of two sides of ball cage retainer.

2、Equipped with three axis CNC system, the processing response speed is faster

3、Double spindle feed can process both sides of the cage at the same time

4、Workpiece hydraulic clamping, large flow cooling, gravity chip removal mechanism design,

5、The double - lead worm gear and worm pair are divided equally, and the degree is accurate.