New energy motor shaft | Deep hole drilling machine motor shaft processing case

Deep hole drilling machine is a kind of high precision, high efficiency, high automation deep hole processing special machine tool, rely on advanced hole processing technology (gun drilling, BTA drilling, jet suction drilling, etc.)

Crafting process

Workpiece case

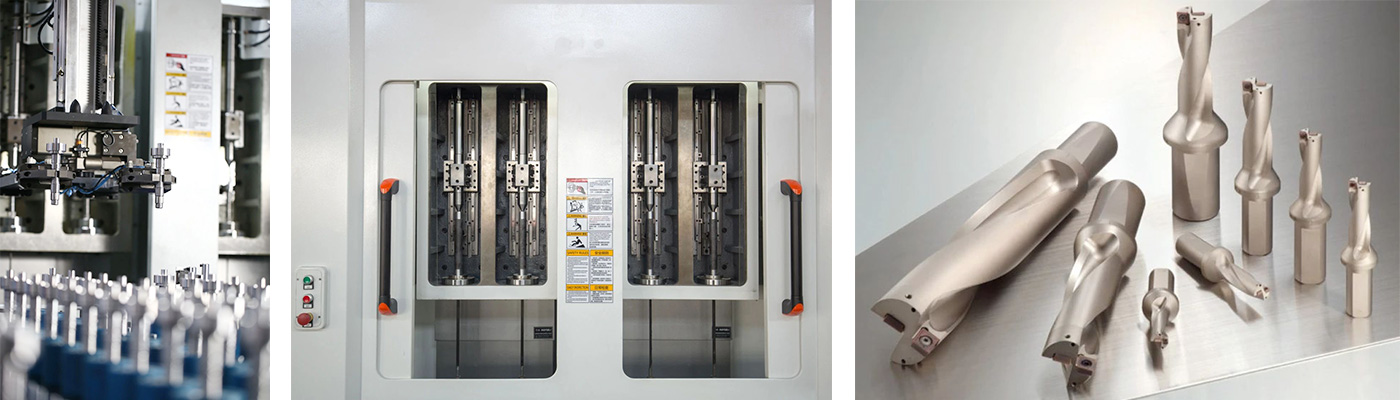

| Workpiece name | New energy motor shaft |

| Machine type | VSMGD0445F |

| Manufacturing procedure | Deep hole drilling |

Deep hole drilling machine is a kind of high precision, high efficiency, high automation deep hole processing special machine tool, rely on advanced hole processing technology (gun drilling, BTA drilling, jet suction drilling, etc.), through a continuous drilling can achieve the general need to drill, expand, reaming process to achieve the processing precision and surface roughness.Machining hole size accuracy: IT7 ~ IT11;Hole deviation: ≤0.5 ~ 1/1000 (hole depth);Surface finish of machining hole: Ra0.2 ~ 6.3um.

It is suitable for deep hole drilling and machining of piston main hole, joint and various shafts of automobile brake pump, direction machine, shock absorber system.

Performance feature

◎ Frame rigid body, linear guide rail, durable

◎ Vertical structure, easy chip removal

◎ High rigidity spindle with special structure, good seismic resistance and long service life

◎ Special hydraulic fixture, hydraulic chuck of special structure, reliable clamping, stable precision;

◎ A variety of fixture optional, should be different workpiece positioning mode

◎ Drilling grab cutting, internal injection type high pressure cooling filter, efficiency block, high precision;

◎ Left and right processing parameters are set independently, which can be processed independently;

◎ It can be equipped with truss or joint robot to support automatic line connection.

Maintenance instructions

1、Cherish the deep hole drilling machine, adhere to the appearance of the deep hole drilling machine and accessories neat, clean;

2、Cutters, tools,jigs and fixtures are arranged neatly;

3、The installation of safety cover such as door switch and anti-collision switch in the operation room of deep-hole drilling machine shall be put into use normally and shall not be disassembled casually.

4、Run the warm-up program before drilling, and if necessary, move each axis of the machine 3-5 times throughout the whole process;

5、Check whether the pressure of hydraulic station is normal once a week;

6、Check the level of cooling oil tank and filter paper once a week.