Technical Parameters

LECN has established a robust marketing and after-sales network across China’s industrial centers and manufacturing hubs, with permanent representative offices in South Korea, Japan, the United Kingdom, Russia, Southeast Asia, and beyond. Serving over 900 customers worldwide, LECN has earned a reputation for precision, durability, and innovation in the field of industrial machine tools.

LECN’s automatic production lines are composed of advanced equipment tailored for shaft processing, spline forming, and CV joint manufacturing. The main machines include:

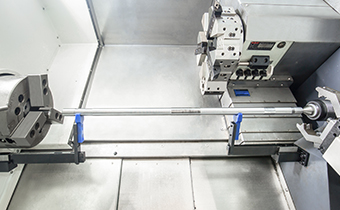

CNC Lathe – Designed for high-precision turning, our CNC lathes ensure consistent quality, faster cycle times, and the ability to handle complex shaft geometries.

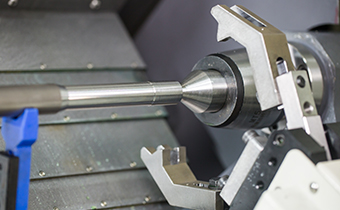

Facing and Centering Machine – With precise alignment and finishing capabilities, this machine guarantees smooth surfaces and optimal concentricity, critical for gearbox and transmission components.

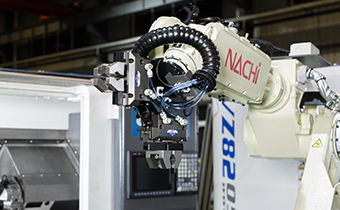

Joint Robot – Our robotic systems automate assembly, reducing labor costs, improving safety, and achieving higher throughput in CV joint and shaft assembly operations.

These machines are part of LECN’s 8 series of over 80 types of special and industrial machine tools, which include:

Precise Rolling Machines

Double-Head Lathes

Grinding Machines

Deep Hole Drilling Machines

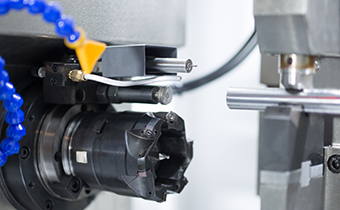

CV Joint Machines

LECN’s production lines are widely adopted in automotive, motorcycle, textile, construction machinery, electric tools, plumbing valves, hardware, and electrical appliance industries, supporting components like gearbox shafts, engine parts, steering systems, braking systems, and constant speed universal joints.

LECN operates in a 30,000+ square meter facility, which houses:

Design and Operation Centers

Testing Centers and Precision Machining Departments

Complete Machine Assembly and Sheet Metal Manufacturing

Equipped with state-of-the-art machining centers, gantry boring and milling machines, gantry guide grinding machines, as well as advanced detection instruments such as gear detection centers, 3D coordinate measuring machines, laser interferometers, and dynamic balance instruments, LECN ensures every machine meets global precision standards.

Even with diversified orders, LECN leverages a supply chain system and ERP management system to guarantee rapid delivery and operational efficiency.

LECN is guided by the enterprise values of:

Self-examination – Continuously improving internal processes

Harmony – Encouraging collaboration and professional integrity

Preciseness – Maintaining the highest manufacturing standards

Freedom – Encouraging innovation and creative solutions

Rooted in China but serving the world, LECN actively responds to user needs with forward-thinking strategies, delivering modern, competitive machinery to industrial customers globally.

Over 20 years of expertise in automatic production lines and special machines

Customized and standardized solutions for CV joint and shaft manufacturing

Global presence with permanent offices in Asia, Europe, and Russia

High-precision, durable machinery suitable for a wide range of industrial applications

Advanced production and testing facilities ensuring consistent quality

LECN ANHUI CO., LTD is your trusted partner for innovative, efficient, and reliable automatic production lines – empowering manufacturers to optimize productivity and maintain competitive advantage.

Application Artifact