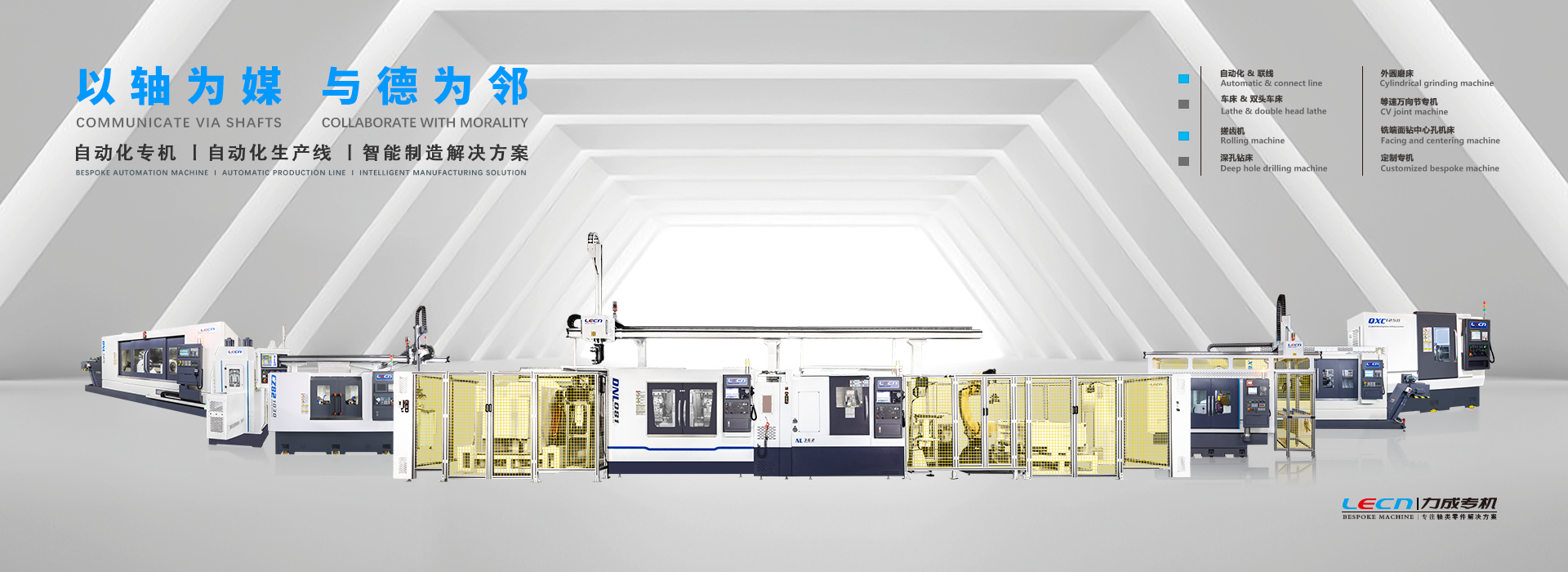

Automatic Production Line

Automatic production lines are characterized by high levels of automation, where tasks such as material handling, machining, assembly, and quality control are performed automatically by machines and equipment. This reduces the need for manual labor and increases production efficiency.

Automatic production lines are designed to operate continuously and efficiently, maximizing throughput and minimizing downtime. They can achieve high production rates and cycle times, resulting in increased productivity and reduced manufacturing costs.

Automated processes in production lines ensure consistent and precise execution of manufacturing tasks, leading to high-quality and uniform products. This improves product reliability and reduces defects and rework.

Our company hot selling Automatic Production line and robot rolling machine.Please contact us.

Technology and Application

Truss Robot And Its Related Technology

Truss robot is a kind of full-automatic industrial equipment based on right angle X, Y and Z coordinate system to adjust the working position of the workpiece or realize the trajectory movement of the workpiece. Its control core is realized by industrial controllers (such as PLC, motion control, single chip microcomputer, etc.). Through the analysis and processing of various input (various sensors, buttons, etc.) signals by the controller, after making certain logical judgment, the controller issues execution commands to each output element (relay, motor driver, indicator light, etc.) to complete the joint movement between the X, Y and Z axes, so as to realize a complete set of fully automatic operation process.