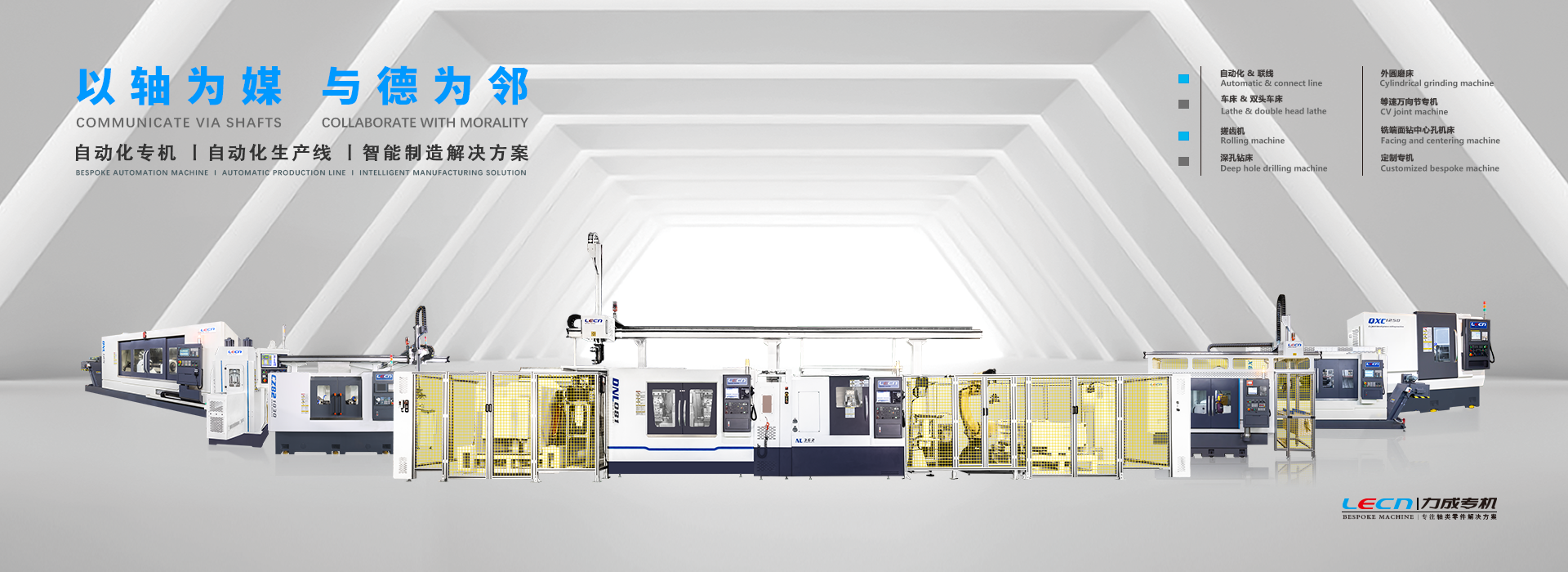

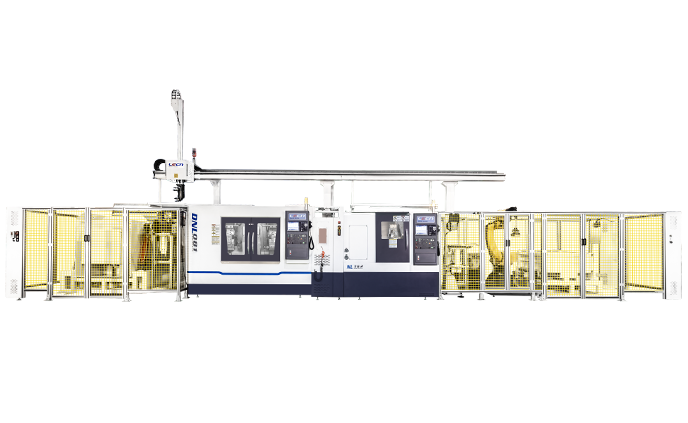

Automatic & Connect Line

Automatic & Connect Line

Lathe & Double Head Lathe

Lathe & Double Head Lathe

Rolling Machine

Rolling Machine

Deep Hole Drilling Machine

Deep Hole Drilling Machine

Cylindrical Grinding Machine

Cylindrical Grinding Machine

CV Joint Machine

CV Joint Machine

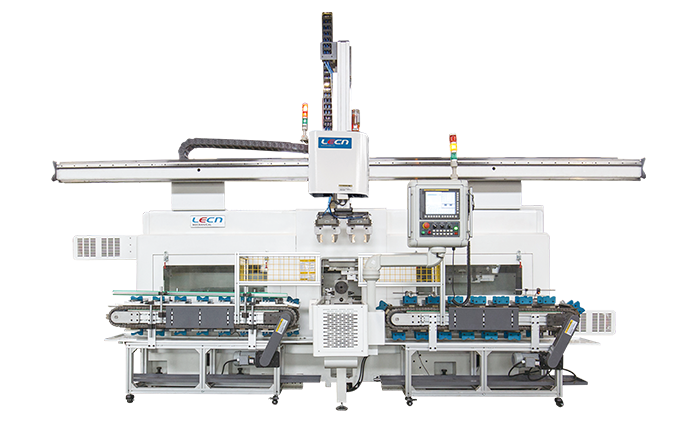

Facing And Centering Machine

Facing And Centering Machine

Customized Bespoke Machine

Customized Bespoke Machine

In the field of external cylindrical machining, cylindrical grinding machine is the key equipment to achieve high-precision cylindrical parts manufacturing. With the advancement of technology, there are not only traditional external cylindrical grinding machines on the market, but also CNC external cylindrical grinding machines equipped with advanced numerical control technology, which can provide higher precision and efficiency. As cylindrical grinding machine manufacturers, they focus on developing and producing various types of grinding machines, including advanced CNC external cylindrical grinding machines, to meet the high-precision machining needs of different industrial fields. Whether it is a basic manually operated model or a high-end automated model, these manufacturers are committed to improving the performance of their products through continuous technological innovation. In addition, choosing a suitable external cylindrical grinding machine is crucial to ensuring machining quality and improving production efficiency, especially when it comes to complex and precise workpieces. Therefore, it is particularly important to cooperate with reliable manufacturers and select suitable equipment according to actual needs.

Cylindrical Grinding Machine is a machine tool specially designed for precision grinding of cylindrical or disc-shaped workpieces. This machine tool is mainly used to manufacture shaft parts with high precision and high-quality surface finish, such as motor shafts, engine crankshafts, etc. Cylindrical grinders are capable of processing workpieces made of various materials, including but not limited to steel, cast iron, ceramics and composite materials.

With the development of computer technology, CNC cylindrical grinders have become mainstream equipment in modern manufacturing. These machines use pre-programmed instructions to automatically perform complex grinding processes, which not only improves processing accuracy and efficiency, but also handles more complex design requirements. CNC cylindrical grinders are particularly suitable for large-scale production because they can significantly reduce setup time and manual intervention while ensuring the consistency and quality of each workpiece.

The working principle of the cylindrical grinder is mainly through the high-speed rotation of the grinding wheel and contact with the workpiece to remove excess material and achieve the desired size and shape. In order to ensure the best processing effect, the cylindrical grinder is usually equipped with a cooling system to reduce the temperature during the grinding process to prevent workpiece deformation and grinding wheel wear. Choosing the right cylindrical grinding machine is crucial to improving production efficiency, reducing costs and improving product quality.

We are always ready to provide you with the best solution to meet the needs of cylindrical grinding machines. Buy low price, high quality CNC cylindrical grinder, choose our products.Please contact us!

Read More

CNC Cylindrical Grinding Machine

CNC Cylindrical Grinding Machine GA2530/GP2530

Max Processing Length: 300 mm

Max Processing Diameter: Ø250 mm

CNC Cylindrical Grinding Machine GA2560/GP2560

Max Processing Length: 600 mm

Max Processing Diameter: Ø250 mm

CNC Cylindrical Grinding Machine GA3560/GP3560

Max Processing Length: 600 mm

Max Processing Diameter: Ø350 mm

CNC Cylindrical Grinding Machine GA35100/GP35100

Max Processing Length: 1000 mm

Max Processing Diameter: Ø350 mm

CBN CNC Cylindrical Grinding Machine

CBN CNC Cylindrical Grinding Machine GP2530H

Max Processing Length: 300 mm

Max Processing Diameter: Ø250 mm

CBN CNC Cylindrical Grinding Machine GP2560H

Max Processing Length: 600 mm

Max Processing Diameter: Ø250 mm

CBN CNC Cylindrical Grinding Machine GP3560H

Max Processing Length: 600 mm

Max Processing Diameter: Ø350 mm

CBN CNC Cylindrical Grinding Machine GP35100H

Max Processing Length: 1000 mm

Max Processing Diameter: Ø350 mm

Technology and Application