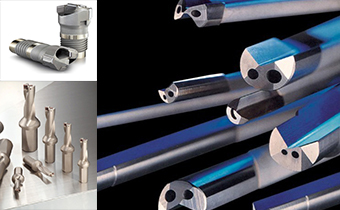

Deep hole drilling machine is a kind of special machine tool for deep hole processing with high precision, high efficiency and high automation. Depending on advanced hole processing technology (gun drill, BTA drill, spray suction drill, etc.), the processing accuracy and surface roughness can be achieved by one continuous drilling process, which generally requires drilling, expanding and reaming processes. Machining hole size accuracy: IT7-IT11; Machining hole deviation: <0.5-1/1000 (Machining hole depth); Machining hole surface finish: Ra0.2-6.3um. It can carry with truss or joint robot and automatical line.

Advantage

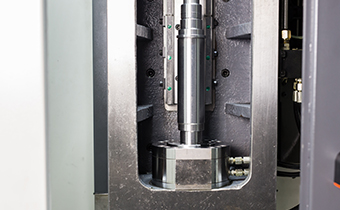

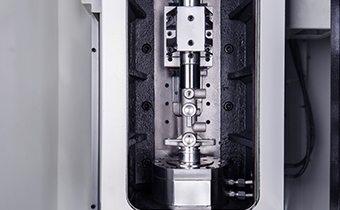

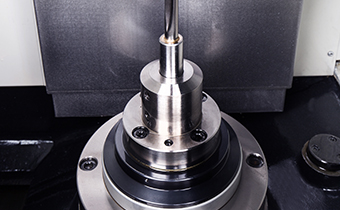

Special hydraulic modular fixture

Special structure, clamping reliable, accuracy stability.

Special high rigidity spindle structure

Seismic resistance, long life.

Variety of tools are available

Gun or BTA or spray suction drill respond to different workpiece.

Automation

Conversational interface,factory high stability automation.

Technical Parameters

| ITEM | VSMGD0445D |

| Max Drilling Diameter, mm | Ø18-Ø40 |

| Max Clamping Diameter, mm | Ø60 |

| Max Workpiece Length, mm | 450 |

| Number Stations | 2 |

LECN’s Deep Hole Drilling Machine is engineered for high-accuracy, high-efficiency drilling of shafts and cylindrical components, critical for automotive, aerospace, and industrial applications. Key features include:

High-Precision Drilling – Maintains strict tolerances, ensuring concentricity and straightness for long and complex shafts.

Durable Construction – Machine body and components are designed to withstand heavy-duty operation while minimizing vibration.

Automation-Ready – Can be integrated into LECN’s automated production lines, improving throughput and reducing manual labor.

Advanced Cooling and Lubrication System – Ensures stable operation and prolongs tool life for deep and continuous drilling tasks.

The Deep Hole Drilling Machine is ideal for applications in:

Automotive shafts (gearbox, engine, transmission)

Motorcycle and power tool components

Construction machinery and industrial equipment

LECN’s Commitment to Quality

LECN operates over 30,000 square meters of production and office space, including:

Design, operation, and testing centers

Precision machining and assembly workshops

Sheet metal and complete machine assembly facilities

Equipped with machining centers, gantry boring and milling machines, gantry guide grinding machines, as well as gear detection centers, 3D coordinate measuring machines, laser interferometers, and dynamic balance instruments, LECN ensures every deep hole drilled component meets international precision standards.

Through ERP-based supply chain management, LECN guarantees timely delivery even for diversified or complex orders.

LECN has served over 900 customers worldwide, becoming a trusted partner in:

Automotive manufacturing (CV joints, transmission shafts, engine components)

Motorcycle production

Textile and construction machinery

Electric tools, plumbing valves, and hardware industries

Our Deep Hole Drilling Machines are recognized for precision, reliability, and durability, helping manufacturers improve efficiency and reduce operational costs.

Over 20 years of R&D experience in specialized machines and production lines

High-precision drilling for long and complex shafts

Integration-ready for automated production lines

Global service network for sales, installation, and after-sales support

Advanced production and testing facilities ensuring consistent quality

LECN ANHUI CO., LTD combines innovation, craftsmanship, and technical expertise, delivering modern deep hole drilling solutions for industrial manufacturers worldwide.

Application Artifact