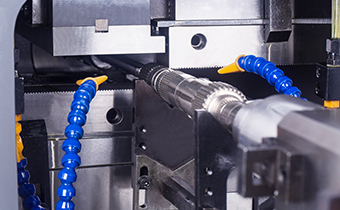

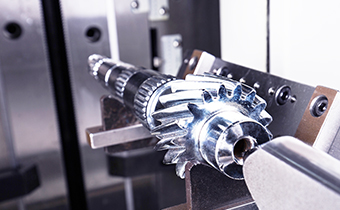

Single or multi section rolling,13 to 36 inch horizontal standard reinforced CNC or hydraulic rolling machine,it is suitable for the precision cold rolling of involute(straight tooth,helical tooth,bevel tooth,missing tooth ,merge tooth)spline,worm,thread,anilox roller,straight grain,oil groove and other precision non chip parts with modulus no more than 1.5.High rigidity,precise,efficient and environmental friendly,it can carry with truss or joint robot and automatical line.

Advantage

Rich mold combination

clamping one time can reverse rolling or rolling few steps, save mold.

Double servo motor full closed-loop drive

Low noise and precise forming process(CNC).

Intelligent all-around top servo technology

Effectively solve clamping secure identification.

Automation

Factory high stability automation.

Technical Parameters

| ITEM | LC1000A | LC1000EA |

| Max Module, mm | 1.5 | 1.5 |

| Max Out Diameter, mm | Ø50 | Ø50 |

| Max Tool Width, mm | 100 | 100 |

| Max Workpiece Length, mm | 1000 | 1000 |

| Max Installing Tool Width, mm | 300 | 300 |

| The Open Part Size, mm | 139.7 | 139.7 |

| Tool Size, inch | 36 or 24、13 | 36 or 24、13 |

| Max Travel, mm | 1160 | 1160 |

| Drive Way | Hydraulic | CNC |

| Special Specifications Can Be Customized | ||

Application Artifact