Sep. 05, 2025

Maintaining a lathe machine is essential for ensuring precision, reliability, and longevity. This guide covers practical daily, weekly, monthly, and quarterly maintenance practices to improve accuracy, reduce breakdowns, and extend equipment life. You’ll learn about essential maintenance tips, common mistakes, necessary tools, and safety measures to keep your lathe performing efficiently in any workshop.

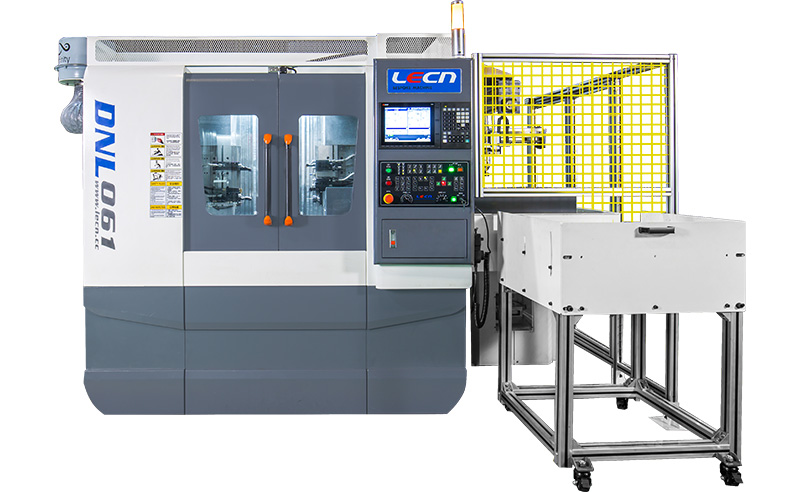

Lathe machines are fundamental in modern manufacturing, widely used in industries such as automotive, aerospace, and metalworking for producing precise components. Both CNC and manual lathes operate under continuous mechanical and thermal stress. Over time, wear on components such as guideways, spindles, and drive systems can affect machining accuracy and efficiency.

Lathe maintenance is not just reactive—it’s proactive. Regular cleaning, lubrication, alignment checks, and timely part inspections prevent failures, protect precision, and help maintain consistent productivity. For operators, this translates to fewer machine breakdowns, lower repair costs, and reliable workflow.

For newcomers to machining, understanding lathe maintenance is crucial. Developing proper habits early ensures long-term accuracy, smooth operation, and safe handling of machinery.

Neglecting maintenance can cause gradual deterioration in performance. Sliding surfaces can wear unevenly, spindle bearings may lose preload, and ball screws can develop backlash. Minor issues—like tool chatter or slight deviations in part dimensions—can escalate, resulting in loss of accuracy and poor surface finishes.

Key components such as guideways, chuck jaws, and drive gears are especially vulnerable. Contaminated way oil can embed abrasive particles into guide surfaces, while worn chuck jaws reduce clamping force, risking part slippage. Replacing these components is costly and requires careful alignment, often causing long downtime.

Coolant and lubrication neglect also leads to corrosion, bearing damage, and increased operating costs. Overall, skipping maintenance affects both machining quality and operational profitability.

Preventive maintenance is most effective when it is consistent and tailored to machine conditions. The following ten tips cover mechanical, electrical, and operational areas essential for maintaining lathe accuracy and longevity:

1. Daily Swarf and Chip Removal

Metal chips act as abrasives, accelerating wear and contaminating lubrication. After each job, remove swarf using a brush or low-pressure air. For machines with conveyors, check for jams and ensure smooth operation. Clean surroundings reduce mechanical wear.

2. Proper Guideway and Slide Lubrication

Guideways rely on an even oil film. Use the correct viscosity (e.g., ISO 68 for general conditions, ISO 220 for heavy loads). Apply evenly; too much oil attracts debris, too little causes stick-slip motion. Maintain a lubrication log for consistency.

3. Lead Screw and Ball Screw Care

Clean screws with lint-free cloths and apply appropriate lubrication—grease for heavy loads, light oil for speed. Inspect seals and wipers for tightness. Monitor backlash and adjust if necessary.

4. Spindle Runout Inspection

Spindle runout impacts accuracy and finish. Use a dial indicator to measure radial and axial runout. Readings beyond tolerance indicate bearing wear or misalignment. Address issues promptly to avoid out-of-spec parts.

5. Turret Indexing Accuracy Check

Ensure the turret positions tools accurately. Check with test cuts or precision gauges. Misalignment can arise from worn locks, hydraulic issues, or disk damage. Adjust per manufacturer guidelines and verify locking force.

6. Coolant Quality and Filtration Maintenance

Coolant regulates heat and flushes chips. Maintain 6–10% concentration for water-soluble types and pH 8–9. Replace clogged filters, remove tramp oil, and flush tanks periodically to prevent corrosion and bacterial growth.

7. Belt and Gear Drive Inspection

Check belts for tension, cracks, or fraying. Inspect gears for wear and ensure proper lubrication. Unusual noise may signal misalignment. Prompt action prevents further damage.

8. Chuck Jaw Cleaning and Lubrication

Remove and clean chuck jaws regularly. Inspect gripping surfaces for wear, lubricate lightly, and verify clamping force. Proper grip prevents slippage or part distortion.

9. Electrical Cabinet Cleaning

Dust can compromise electrical performance. Power down before opening. Use low-pressure air or vacuum to remove dust, tighten terminals, and check fan operation. Replace air filters to prevent overheating.

10. Machine Leveling and Alignment

Leveling affects accuracy and long-term wear. Use a machinist’s level or laser system to check bed twist. Adjust leveling screws to maintain tolerances, preventing uneven cuts and excessive bearing load.

Organizing tasks by daily, weekly, monthly, and quarterly intervals ensures consistent attention to all critical areas:

Daily: Remove swarf, check lubrication levels, and monitor coolant concentration and pH.

Weekly: Lubricate slides, clean fixtures and chucks, inspect lead screws and ball screws, and check backlash.

Monthly: Measure spindle runout, verify turret indexing, inspect coolant filtration, and flush tanks as needed.

Quarterly: Full preventive inspection—clean electrical cabinet, replace air filters, level machine, inspect belts, gears, and lubrication systems, and replace worn components.

Using the Wrong Lubricant: Reduces load-carrying capacity and causes scoring. Always use manufacturer-recommended oils.

Ignoring Coolant Quality: Can lead to rust, poor lubrication, and tool wear. Monitor concentration and pH regularly.

Skipping Cleaning: Chips act as abrasives and can clog filters.

Overlooking Alignment Checks: Minor misalignment can cause tapered cuts and excessive wear.

Delaying Small Repairs: Promptly replace worn belts, wipers, and filters to prevent secondary damage.

Precision Instruments: Dial indicators, machinist’s level, feeler gauges.

Lubrication & Cleaning Equipment: Oil guns, grease guns, lint-free cloths.

Coolant Testing Tools: Refractometer, pH strips or digital meters.

Consumables: Way oil (ISO 68/220), anti-rust oil, quality coolant.

Store all materials properly, keep instruments protected, and follow manufacturer guidelines for safe and effective maintenance.

Power Isolation: Use lockout/tagout (LOTO) procedures before maintenance.

PPE: Safety glasses, gloves, and hearing protection as needed. Avoid loose clothing.

Handling Chemicals: Mix coolants safely, wear chemical-resistant gloves, and work in ventilated areas.

Moving Parts: Ensure all axes are stopped before adjustments. Stand clear when testing.

Electrical Safety: Use insulated tools, check wiring, and never bypass interlocks.

Tool & Lifting Safety: Use appropriate tools and hoists. Secure loads properly.

Following safety practices ensures maintenance is effective and accident-free.

Consistent lathe maintenance is a strategic investment. Proper care preserves machining accuracy, reduces downtime, and extends machine life. By implementing preventive routines, operators can maintain quality, control costs, and ensure reliable production. Combining disciplined habits with correct tools and safe procedures ensures lathe machines remain productive and accurate for years.

Previous: None

Next: None