Cylindrical grinding is a core process in modern machining, known for its precision and ability to produce smooth finishes. Whether external, internal, or both, cylindrical grinding is essential for manufacturing components in automotive, aerospace, and other high-precision industries.

With so many CNC cylindrical grinders on the market, selecting the right one can be challenging. In this guide, LECN helps you navigate the decision-making process by outlining the key features to consider when choosing a cylindrical grinder that meets your operational goals.

1. Size Matters: Compact vs. Full-Scale Solutions

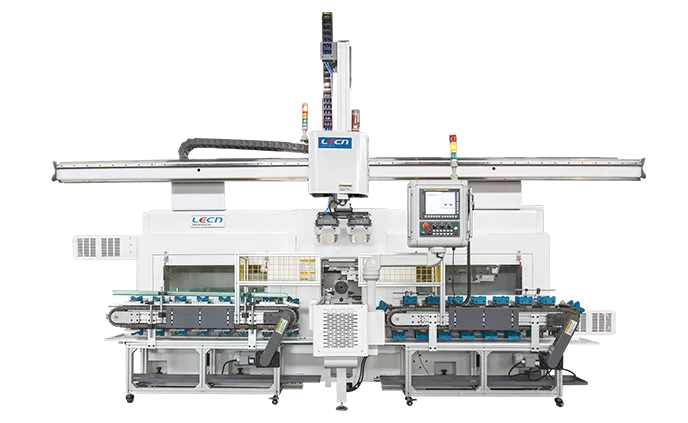

If your workshop is space-constrained, compact machines like the LECN WPG 7 offer excellent functionality in a small footprint. Designed with integrated systems—including electrical, cooling, and lubrication—these machines are ideal for precise external grinding of small components.

2. Flexibility in Loading: Automation vs. Manual Operation

Manual Loading: Best for low-volume production or prototyping, offering flexibility and control.

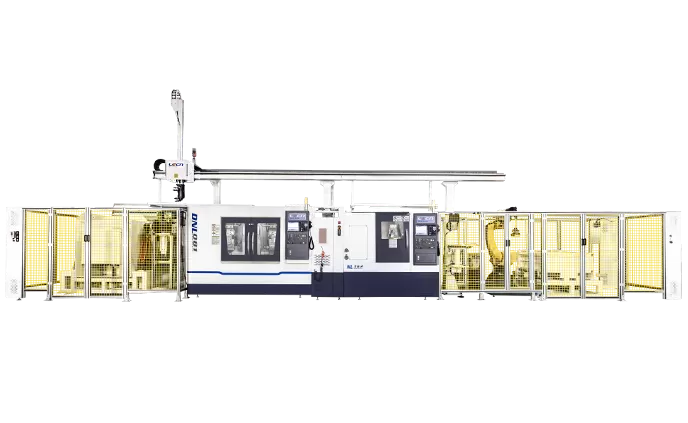

Automated Loading: Ideal for medium to high-volume production. Integrated gantry systems can be connected to conveyors, robots, or pallets for continuous, efficient part handling.

3. Grinding Configurations: Straight vs. Angular Plunge-Cut

LECN grinders support both configurations:

Straight Plunge-Cut: Best for linear profile grinding.

Angular Plunge-Cut: Suitable for complex geometries and angled profiles.

4. Advanced Monitoring and Control Systems

LECN CNC grinders feature cutting-edge process controls to ensure consistent quality and safety:

In-process measurement systems for real-time diameter monitoring

GAP and crash detection to prevent damage

Automatic balancing to minimize vibration and extend wheel life

5. Ease of Operation: CNC Interface and Programming

LECN machines use intuitive CNC systems such as FANUC for fast setup and easy parameter adjustment. Dialog-based interfaces reduce training time while maintaining precision and repeatability.

6. Tailored Solutions for Specialized Needs

LECN offers grinders with custom configurations, including modular designs, wheel profiling, and adjustable head angles—perfect for production environments with evolving requirements.

7. Durability and Thermal Stability

Rigid Construction: Minimizes vibration, ensuring accuracy during operation.

Efficient Heat Management: Reduces thermal deformation, maintaining micrometer-level tolerances.

8. Fast Installation and Deployment

Machines like the LECN WPG 7 offer plug-and-play setup, requiring only electrical and air supply connections. Installation can be completed in under four hours, minimizing production downtime.

Conclusion: A Strategic Investment in Precision

Choosing the right cylindrical CNC grinder from LECN means more than meeting today’s needs—it’s about securing your future production capabilities. With options for compact design, automation, and high-performance control, LECN grinding solutions are built to support precision, scalability, and long-term success.

Take the time to assess your requirements. The right machine isn't just equipment—it's a competitive advantage for your manufacturing business.